Yes, you can call a robot position from a PLC. This process involves communication between the PLC and the robot controller.

In modern manufacturing, automation plays a crucial role. PLCs, or Programmable Logic Controllers, control machinery and processes. Robots, on the other hand, handle tasks with precision and efficiency. Integrating these systems can improve productivity and reduce errors. But how does one make a robot move to a specific position using a PLC?

This blog explores the steps and considerations for successful communication and control. Whether you’re a seasoned engineer or new to automation, understanding this integration is essential for optimizing your operations. Let’s dive into the details and discover how to make it work.

Credit: www.fanucamerica.com

Contents

Introduction To Robotics And Plc

Understanding the synergy between robotics and PLC is essential in modern automation. Robotics and Programmable Logic Controllers (PLC) play critical roles in various industries. This post will delve into their significance and how they work together.

Role Of Robotics In Automation

Robots streamline manufacturing processes. They execute tasks with precision and speed. These machines reduce human error. They also enhance productivity. Robotics can handle repetitive tasks. This allows human workers to focus on complex duties. Robots are also used in hazardous environments. They ensure worker safety by performing dangerous tasks.

Importance Of Plc In Industrial Automation

PLC systems control machinery and processes. They are the backbone of industrial automation. PLCs are known for their reliability. They operate under harsh conditions without failing. These systems are easy to program. They can be tailored to specific needs. PLCs monitor and control sensors and actuators. This ensures smooth operation of the entire system. Combining robotics and PLCs leads to efficient and safe automation. This integration ensures seamless communication between machines. It enhances overall productivity and reliability.

Credit: www.solisplc.com

Communication Between Robots And Plcs

Robots and PLCs can interact effectively. Yes, a robot position can be called from a PLC. This integration allows precise control in automated systems.

Connecting robots and PLCs can improve automation. This connection allows for better control and efficiency. Understanding how they communicate is key.

Protocols For Communication

Robots and PLCs use various communication protocols. Common ones include Ethernet/IP, PROFINET, and Modbus. These protocols help them exchange data quickly and accurately. Ethernet/IP is widely used due to its reliability. PROFINET offers high-speed communication. Modbus is simple and effective for many applications. Choosing the right protocol depends on your system needs.

Common Challenges

Despite the benefits, challenges exist in communication. Compatibility is a major issue. Not all robots and PLCs use the same protocols. This can cause integration problems. Latency is another challenge. Delays in data transfer can affect performance. Ensuring real-time communication is crucial. Proper network setup can help reduce latency. Security is also a concern. Unauthorized access can disrupt operations. Implementing strong security measures is essential. Regular updates and monitoring can prevent breaches. “`

Steps To Call A Robot Position From Plc

In today’s industrial environment, integrating robots with Programmable Logic Controllers (PLCs) is essential. This integration allows for seamless automation and precise control. Calling a robot’s position from a PLC can streamline operations and improve efficiency. Let’s explore the steps involved in this process.

Setting Up The Plc

Setting up the PLC is the first step in calling a robot’s position. Here are the necessary steps:

- Identify Communication Protocol: Determine the protocol used by both the PLC and the robot. Common protocols include Ethernet/IP, Modbus, and Profinet.

- Connect the PLC: Physically connect the PLC to the robot. Use appropriate cables and ports.

- Configure Network Settings: Set the IP address and subnet mask for the PLC. Ensure it matches the network configuration of the robot.

- Program the PLC: Write a simple program to test communication. Send a basic command to the robot and verify the response.

Configuring The Robot

Configuring the robot is equally important. Follow these steps:

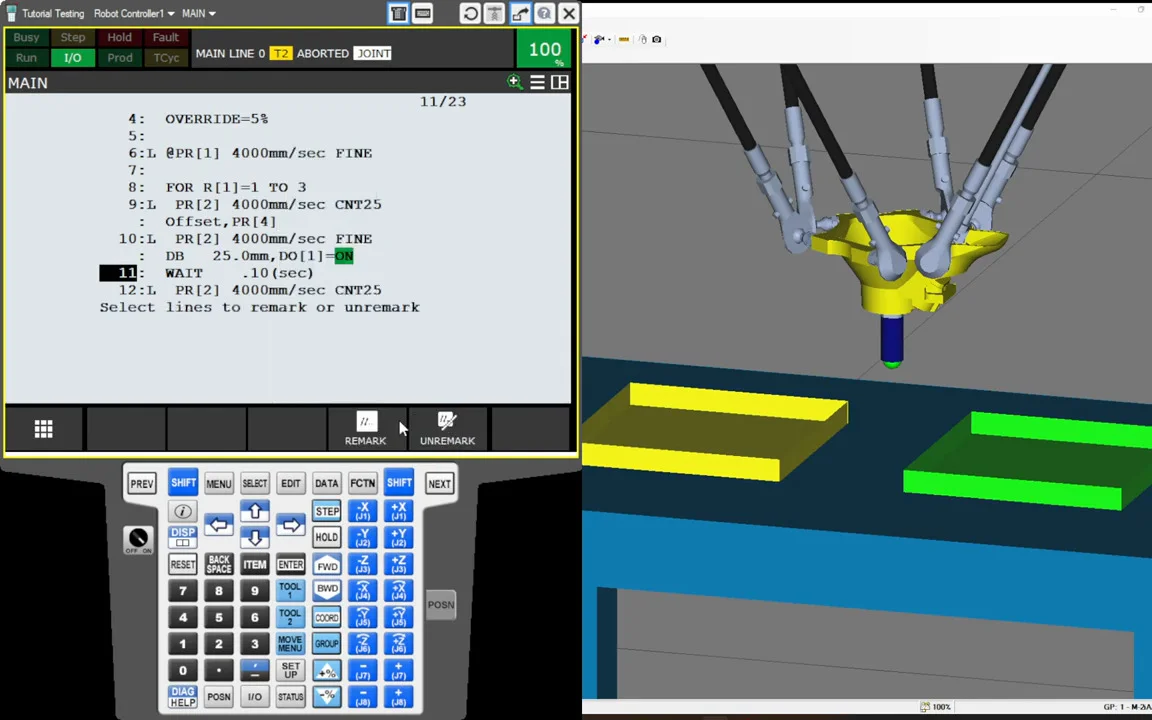

- Access Robot Controller: Use the robot’s teach pendant or software interface to access the controller settings.

- Set Communication Parameters: Configure the communication settings on the robot. Match these settings with the PLC’s network configuration.

- Define Robot Positions: Use the teach pendant to define the specific positions the robot will move to. Save these positions in the robot’s memory.

- Test Communication: Send a command from the PLC to move the robot to a defined position. Verify the robot moves correctly.

By following these steps, you can successfully call a robot position from a PLC. This process enhances automation and ensures precise control of robotic operations.

Programming The Plc

To call a robot position from a PLC, you need to program the PLC correctly. This involves understanding the basics of PLC programming and then advancing to more complex techniques. Here is a guide to help you through the process.

Basic Plc Programming

Start with the basic concepts of PLC programming. The foundation is essential. You will need to know how to create a simple program to control your robot. This typically involves:

- Ladder logic: The most common programming language for PLCs.

- Inputs and outputs: These are the signals your PLC will send and receive.

- Timers and counters: These help control the timing of your robot’s movements.

For example, you might have an input from a sensor that tells the PLC the robot is in position. The PLC then sends an output signal to the robot to move to the next position.

Advanced Techniques

Once you have mastered the basics, you can move on to advanced techniques. These include:

- Subroutines: These are smaller programs within your main program. They help to organize and reuse code.

- Data handling: Storing and retrieving data efficiently is crucial. Use data registers for this.

- Communication protocols: Your PLC needs to communicate with other devices. Learn about protocols like Modbus or Ethernet/IP.

Here is an example of a simple ladder logic program:

|----[ Start ]----[ Sensor ]----|----( Move Robot )----|

This program checks if the start button is pressed and the sensor is triggered. If both conditions are met, the robot moves. As you advance, you can add more logic and conditions to your program. This allows for more precise control of the robot.

Integrating Robot And Plc

Integrating robots and PLCs can enhance automation. It allows for precise control. This integration improves productivity and efficiency. Many industries benefit from this technology. It is crucial to understand how to make this connection work.

Establishing Connection

First, establish a connection between the robot and the PLC. Use the right communication protocols. Ethernet, Modbus, and Profinet are common choices. Ensure both devices support the chosen protocol. Set the IP addresses correctly. Match the settings on both ends. This step is vital for smooth communication.

Synchronizing Movements

Next, synchronize the movements of the robot and the PLC. Programming both devices is necessary. Use the PLC to send commands to the robot. The robot executes these commands. Timing is key in this process. Ensure the PLC and robot work in harmony. Proper synchronization avoids collisions and errors.

Testing And Troubleshooting

Testing and troubleshooting are essential steps in ensuring the proper functioning of robots called from a PLC. These steps help identify any issues and ensure smooth operation. By following a systematic approach, you can diagnose and fix problems effectively.

Identifying Common Issues

Identifying common issues is the first step in troubleshooting. Check the communication between the PLC and the robot. Ensure that the connection is stable. Look for any error messages on the PLC display. These messages can provide clues about what might be wrong. Verify that the robot’s position data is correct. Incorrect data can lead to positioning errors. Inspect the wiring and connectors for any signs of damage or loose connections. These physical issues can disrupt communication.

Ensuring Smooth Operation

Ensuring smooth operation involves several checks. Make sure that the PLC program is correctly configured. The program should be set up to call the robot positions accurately. Test the system by running a few cycles. Observe the robot’s movements closely. Check the robot’s calibration. A miscalibrated robot can lead to positioning errors. Regularly update the robot’s firmware and software. Updates often contain bug fixes and improvements. Keep the PLC software updated as well. Document any issues and their solutions. This documentation can be helpful for future troubleshooting. Regular maintenance and testing can prevent many common issues.

Real-world Applications

Robots and PLCs are integral to modern industries. They ensure precision, efficiency, and safety. Let’s explore how calling a robot’s position from a PLC works in real-world scenarios. We will focus on two main areas: manufacturing and logistics.

Manufacturing

In manufacturing, robots and PLCs collaborate to streamline production. PLCs control robots to perform tasks like welding, assembly, and painting. They send precise commands to ensure robots move to the correct positions. This automation reduces human error and speeds up production. Factories use PLCs to adjust robot positions for different tasks. This flexibility improves efficiency and product quality. Robots can handle dangerous tasks, enhancing worker safety. PLCs ensure these robots operate in sync with other machinery. This coordination boosts overall productivity in manufacturing plants.

Logistics

In logistics, robots and PLCs improve warehouse operations. PLCs direct robots to pick and place items accurately. This automation speeds up order fulfillment and reduces errors. Robots can navigate complex warehouse layouts efficiently. PLCs provide the necessary commands for these movements. They ensure robots avoid obstacles and follow the best paths. Warehouse managers can reprogram PLCs to adapt to changing demands. This adaptability helps meet varying customer requirements. Robots and PLCs working together optimize storage and retrieval processes.

Future Trends In Automation

Automation is rapidly evolving. It has become a key player in modern industries. Robots and PLCs (Programmable Logic Controllers) are at the heart of this transformation. The ability to call a robot position from a PLC is gaining attention. This blog section will explore future trends in automation.

Emerging Technologies

Several technologies are shaping the future of automation. Artificial intelligence (AI) is a prime example. AI allows robots to learn and adapt. This increases efficiency in operations. The Internet of Things (IoT) connects devices. It enables seamless communication between robots and PLCs. This connectivity improves data sharing and decision-making. Augmented Reality (AR) is also making its mark. AR helps in remote troubleshooting and maintenance. It enhances the interaction between humans and machines.

Impact On Industries

Automation trends are affecting various industries. Manufacturing is seeing significant changes. Robots perform tasks with precision and speed. This reduces human error and increases productivity. The automotive industry uses robots for assembly lines. This ensures consistent quality and faster production rates. The healthcare sector benefits from automation too. Robots assist in surgeries and patient care. This improves outcomes and efficiency. The logistics industry uses automated systems for inventory management. This streamlines operations and reduces costs.

Credit: www.vaughn.edu

Frequently Asked Questions

How Can A Plc Call A Robot Position?

A PLC can call a robot position by sending specific commands to the robot’s controller through communication protocols.

What Are The Benefits Of Using Plc With Robots?

Using PLC with robots improves automation, increases precision, and enhances coordination between different machines in a production line.

Can Any Plc Communicate With Any Robot?

Not all PLCs can communicate with all robots. Compatibility depends on the communication protocols and interfaces used.

Conclusion

Using a PLC to call a robot position offers many advantages. It simplifies automation processes and improves efficiency. You can control robots more precisely. Integrating PLC and robots enhances production workflows. This method is reliable and effective. Understanding the basics helps in implementing it successfully.

Try it in your projects for better results. Embrace technology to stay competitive in your industry. Happy automating!