Yes, you can call a robot position from a PLC. This process allows for precise control and coordination in automated systems.

It ensures that robots perform tasks efficiently and accurately. In modern manufacturing and automation, PLCs (Programmable Logic Controllers) play a vital role. They manage and control machinery, ensuring smooth operations. Integrating robots with PLCs enhances system functionality. Robots can perform complex tasks, but they need precise instructions.

By calling robot positions from PLCs, you ensure seamless integration and coordination. This interaction helps in achieving high efficiency in automated processes. Understanding how to call a robot position from a PLC is crucial for optimizing automation. In this blog, we will explore the steps and benefits of this integration. Let’s dive in and learn how to improve your automation setup.

Credit: www.solisplc.com

Contents

- 1 Introduction To Plc And Robotics

- 2 Interfacing Plc With Robots

- 3 Setting Up The Plc System

- 4 Programming The Plc For Robot Control

- 5 Robot Positioning Techniques

- 6 Sending Position Commands From Plc

- 7 Monitoring And Feedback

- 8 Advanced Tips And Best Practices

- 9 Case Studies And Applications

- 10 Frequently Asked Questions

- 11 Conclusion

Introduction To Plc And Robotics

Understanding how to call a robot position from a PLC can be a complex task. To make it simpler, we first need to understand the basics of PLC and the role of robotics in automation. This knowledge will help us grasp the concept better and make the process easier to follow.

Basics Of Plc

A Programmable Logic Controller (PLC) is a digital computer used in industrial settings. It controls machinery and processes. PLCs are designed for real-time use. They are robust and can withstand harsh environments. Engineers use PLCs to automate tasks and enhance efficiency. PLCs use ladder logic programming. This graphical language is easy to understand. It resembles electrical relay logic. The PLC reads inputs from sensors and switches. It then makes decisions based on the logic programmed and sends outputs to actuators and other devices.

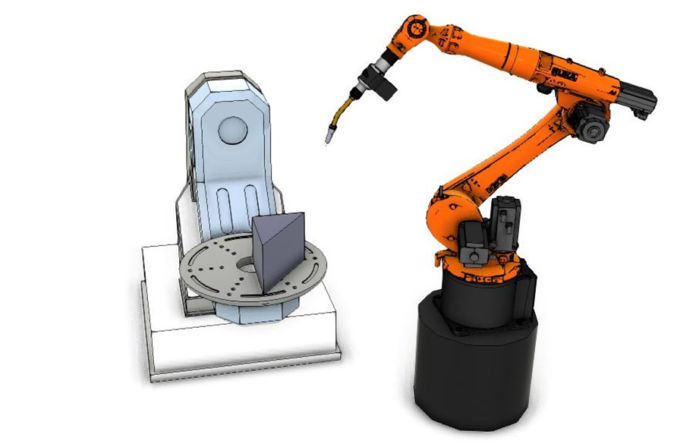

Role Of Robotics In Automation

Robotics plays a crucial role in automation. Robots can perform repetitive tasks with high precision. They improve productivity and reduce human error. In manufacturing, robots handle tasks like welding, painting, and assembling. In warehouses, they assist in sorting and moving items. Integrating robots with PLCs enhances their capabilities. PLCs can control the robot’s movements. This integration allows for more complex and precise operations. It also improves coordination between different parts of the system. The result is a more efficient and reliable automation process.

Interfacing Plc With Robots

Interfacing a PLC with robots opens up many possibilities in automation. PLCs, or Programmable Logic Controllers, control automated systems. Robots, on the other hand, perform tasks with precision. Combining these two creates an efficient and flexible system. This section will explore the essential aspects of interfacing PLCs with robots.

Communication Protocols

Communication protocols are vital for PLC and robot interfacing. These protocols ensure that data is exchanged correctly. Common protocols include Ethernet/IP, Modbus, and Profinet. Ethernet/IP is widely used due to its speed and reliability. Modbus is simple and effective for many applications. Profinet provides real-time data exchange, which is crucial in high-speed environments.

Hardware Requirements

Connecting a PLC to a robot requires specific hardware. The PLC must have the right communication ports. These could be Ethernet ports, serial ports, or special communication modules. Robots also need compatible interfaces. Some robots come with built-in PLC interfaces. Others might need additional modules. Ensuring compatibility between the PLC and robot hardware is crucial for seamless communication.

Setting Up The Plc System

Setting up the PLC system is a crucial step to calling a robot position. You need to ensure proper setup to avoid errors. Let’s dive into the initial steps.

Choosing The Right Plc

Choosing the right PLC is essential for your system’s success. Different PLCs offer various features and capabilities. Consider these factors:

- Compatibility: Ensure the PLC is compatible with your robot.

- Performance: Choose a PLC that meets your performance needs.

- Scalability: Select a system that can grow with your needs.

Here is a comparison table to help you decide:

| Feature | PLC A | PLC B |

|---|---|---|

| Compatibility | High | Medium |

| Performance | High | Low |

| Scalability | Yes | No |

Initial Configuration Steps

The initial configuration steps are vital for a smooth setup. Follow these steps to get started:

- Power Up: Connect the PLC to a power source.

- Connect to Network: Link the PLC to your network.

- Install Software: Install the necessary PLC software on your computer.

- Configure IP Address: Set the PLC’s IP address in the software.

- Load Program: Load your initial program to the PLC.

- Test Connection: Verify the connection between the PLC and the robot.

These steps ensure your PLC is ready to communicate with the robot. It’s important to follow each step carefully to avoid issues later.

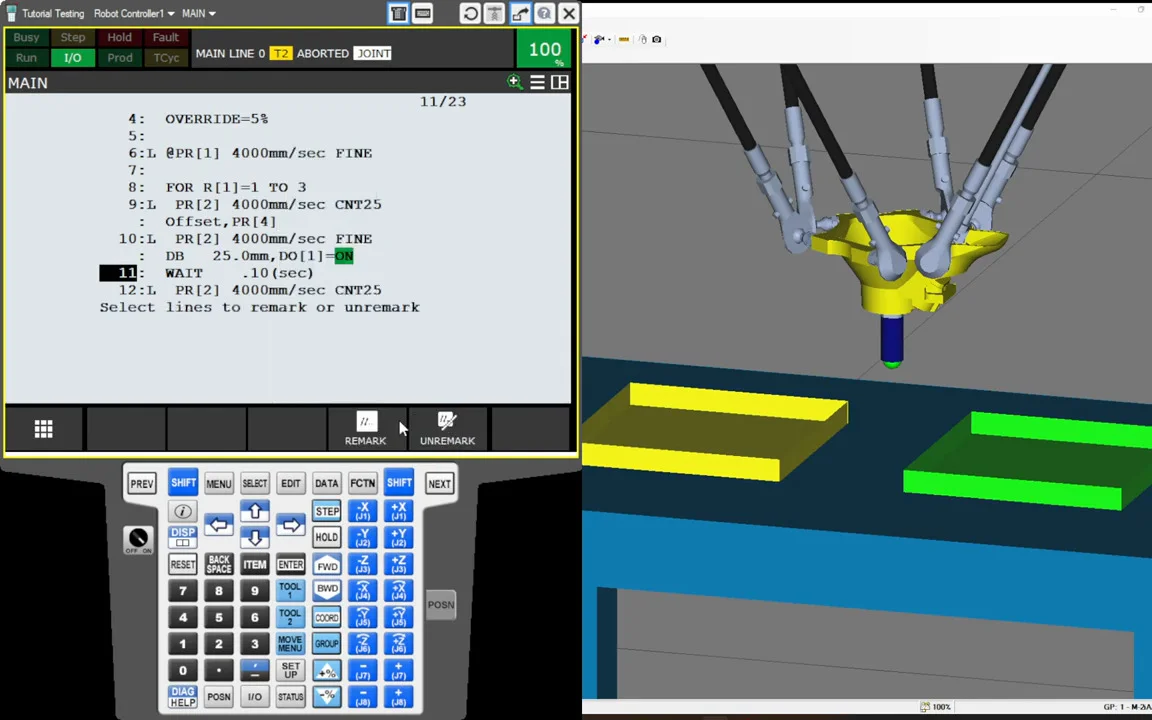

Programming The Plc For Robot Control

Programming a PLC to control a robot position requires precision and accuracy. The process involves writing control code and then testing and debugging it. Each step plays a crucial role in ensuring the robot operates correctly. Let’s explore these steps in detail.

Writing The Control Code

The first step is writing the control code. This code will send commands from the PLC to the robot. Begin by defining the robot’s movements and positions. Use simple instructions to avoid errors. Ensure that each command is clear and concise. Next, integrate these instructions into the PLC’s programming environment. Many PLCs use ladder logic for this purpose. Ladder logic is visual and easy to understand. It helps in organizing the control code effectively.

Testing And Debugging

Once the control code is written, testing follows. Testing verifies if the code executes correctly. Connect the PLC to the robot and run the program. Observe the robot’s movements. Ensure they match the defined positions. If the robot does not move as expected, debugging is necessary. Check the control code for errors. Correct any mistakes found. Test the program again after making corrections. Repeat this process until the robot performs accurately. Testing and debugging ensure the robot operates smoothly. It minimizes the risk of errors in real-world applications. Thorough testing guarantees reliable robot control through the PLC.

Robot Positioning Techniques

Understanding robot positioning is essential for precise and efficient operations. The right technique ensures that robots perform tasks accurately. This section explores two key aspects of robot positioning: Absolute vs. Relative Positioning and Coordinate Systems.

Absolute Vs. Relative Positioning

Robots use positioning to know where they are in space. There are two main types:

- Absolute Positioning: This method gives the robot a fixed position. It uses a defined point of origin.

- Relative Positioning: This method bases the robot’s position on its last known location. It is useful for tasks requiring flexibility.

Absolute positioning ensures high accuracy. It is best for tasks that need exact repetition. Relative positioning offers more adaptability. It suits tasks where the environment changes often.

Coordinate Systems

Robots operate within defined coordinate systems. These systems help them understand their environment. There are three main types:

| Coordinate System | Description |

|---|---|

| World Coordinate System | This is the global reference frame. All positions are measured from a fixed point in the world. |

| Tool Coordinate System | This frame moves with the robot’s tool. It is useful for tasks involving the robot’s end effector. |

| Base Coordinate System | This frame is fixed to the robot’s base. It helps in defining positions relative to the robot’s base. |

These coordinate systems help in defining robot positions with clarity. Knowing these systems helps in programming the robot more effectively.

Credit: www.solisplc.com

Sending Position Commands From Plc

Sending position commands from a PLC to a robot can be a complex task. However, with a clear understanding of the command syntax and practical examples, it becomes manageable. This section will delve into the details of how to send these commands effectively.

Command Syntax

To control a robot’s position, you must use specific commands. These commands follow a particular syntax. Here’s a breakdown:

- Command Name: This specifies the action to be performed.

- Parameters: These define the details of the command, such as position coordinates.

The basic structure looks like this:

MOVE X Y ZIn this example, MOVE is the command, and X, Y, and Z are the coordinates.

Practical Examples

Let’s look at some practical examples. These will help you understand how to send position commands:

- Moving to a Specific Point:

To move the robot to coordinates (10, 20, 30), you would use:

MOVE 10 20 30- Returning to Home Position:

To return the robot to its home position, you might use:

MOVE 0 0 0These simple commands demonstrate basic movement. For more complex tasks, you can add additional parameters. Here’s a table summarizing some common commands:

| Command | Description |

|---|---|

| MOVE | Move to specific coordinates |

| HOME | Return to home position |

| STOP | Stop all movements |

Understanding these commands is crucial. It ensures precise and safe robot operations. Practice these commands to gain confidence in controlling your robot through a PLC.

Monitoring And Feedback

Monitoring and feedback are crucial for ensuring that robots and PLCs work together seamlessly. It helps in maintaining the efficiency of the system and ensures that any issues are quickly identified and resolved. Let’s dive into the importance of real-time monitoring and error handling in this process.

Real-time Monitoring

Real-time monitoring allows you to track the robot’s activities as they happen. This means you can see the robot’s position, speed, and other parameters instantly. It helps in making immediate adjustments if needed. Using a PLC, you can set up a control system to monitor the robot continuously. This involves:

- Tracking the robot’s position

- Monitoring speed and acceleration

- Checking for deviations from the expected path

Real-time data is crucial for maintaining precision. It helps in optimizing the robot’s performance and ensuring safety.

Error Handling And Corrections

Errors can occur in any automated system. Handling these errors swiftly is essential to avoid downtime and potential damage. A PLC can help in identifying and correcting errors quickly. Key aspects of error handling include:

- Detecting errors in real-time

- Logging error details for analysis

- Implementing corrective actions immediately

For instance, if a robot deviates from its path, the PLC can immediately halt operations. It then sends an alert to the operator. This ensures that issues are addressed before they escalate. Incorporating error handling mechanisms improves the reliability of the system. It reduces the need for manual intervention and increases productivity.

Credit: www.fanucamerica.com

Advanced Tips And Best Practices

Integrating robots with PLCs can enhance automation efficiency. To achieve optimal results, follow these advanced tips and best practices. This section offers insights into optimizing performance and ensuring safety.

Optimizing Performance

To achieve seamless communication between your PLC and robot, consider these steps:

- Fine-tune communication protocols: Ensure your PLC and robot use compatible protocols.

- Optimize data transmission: Minimize data packet size for faster transfer.

- Regular updates: Keep firmware and software updated for best performance.

Analyze performance metrics regularly. This helps identify potential bottlenecks. Consider using a performance monitoring tool for real-time insights.

Ensuring Safety

Safety is crucial when integrating robots with PLCs. Follow these best practices:

| Best Practice | Description |

|---|---|

| Emergency Stop Mechanism | Install a reliable emergency stop button within reach. |

| Safety Interlocks | Use interlocks to prevent unsafe operations. |

| Regular Inspections | Conduct routine checks to ensure all safety systems work. |

Train your staff on safety protocols. Knowledgeable operators can quickly respond to emergencies. Use clear, simple instructions.

Case Studies And Applications

PLC (Programmable Logic Controllers) are becoming integral in robotics. They offer a reliable way to control robots in various industries. This section explores real-world examples and future trends.

Industrial Examples

In manufacturing, PLCs help in assembly lines. They control robotic arms to ensure precision and speed. For example, a car assembly plant uses PLCs to position welding robots. This ensures each weld is in the exact spot. Another example is the food industry. PLCs manage packaging robots. They position the robots to pack products efficiently. This reduces waste and increases productivity. In the pharmaceutical industry, PLCs control robotic dispensers. They ensure the right amount of medication is dispensed. This improves accuracy and safety.

Future Trends

The future of PLCs in robotics is promising. Artificial Intelligence (AI) integration is one trend. AI can enhance PLC capabilities. This allows more complex tasks to be automated. Another trend is the Internet of Things (IoT). IoT enables PLCs to connect with other devices. This improves data sharing and decision-making. Wireless communication is also emerging. It allows PLCs to control robots without cables. This increases flexibility in robot positioning.

| Industry | Application | Benefits |

|---|---|---|

| Manufacturing | Assembly Lines | Precision, Speed |

| Food | Packaging | Efficiency, Reduced Waste |

| Pharmaceutical | Dispensing | Accuracy, Safety |

Frequently Asked Questions

Can A Plc Control A Robot’s Position?

Yes, a PLC can control a robot’s position. It sends commands to the robot.

How Do Plcs Communicate With Robots?

PLCs communicate with robots via standard protocols. Examples include Ethernet/IP, Modbus, or ProfiNet.

What Are The Benefits Of Using Plcs With Robots?

Using PLCs with robots improves automation. It allows for precise control and coordination.

Conclusion

Connecting a robot to a PLC is possible and practical. It enhances automation efficiency. You can achieve precise control and coordination. With proper programming, tasks become seamless. Robots and PLCs work together to optimize processes. This integration is crucial for modern industries.

Start exploring this technology today. Improve your production line’s capabilities. Embrace the future of industrial automation.