Human-Machine Interfaces (HMIs) are integral to modern industrial automation and control systems. They bridge the gap between complex machinery and human operators, enabling control, monitoring, and diagnostics. HMI programming, therefore, plays a pivotal role in ensuring that operators can efficiently interact with machines, making systems more efficient, user-friendly, and safe.

In this blog post, we will delve deep into the essentials of HMI programming. We’ll explore what HMI programming is, its importance, and the key components involved in the development of effective HMI systems. Additionally, we will highlight best practices, tools, and industry insights to help you get started with HMI programming.

What is HMI Programming? Essential Tips for Building Effective Human-Machine Interfaces

Contents

What is HMI Programming?

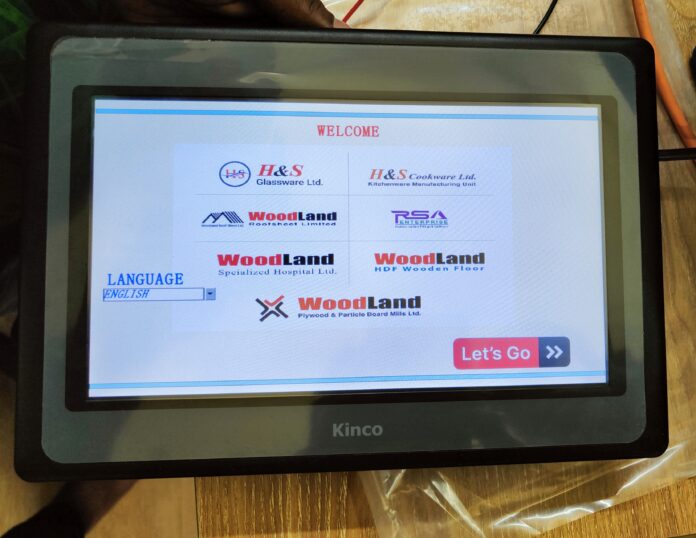

HMI programming refers to the process of designing and developing software applications that allow users to interact with automated systems via graphical interfaces. It involves creating the visual elements (such as buttons, gauges, and indicators) and defining the logic that controls the interaction between the user and the machine. HMIs are commonly used in industries like manufacturing, automotive, energy, and utilities to provide real-time data visualization, system control, and troubleshooting.

Key Components of HMI Programming

HMI systems typically consist of the following components:

- Hardware: The physical interface that users interact with, such as a touchscreen or control panel. It may also include specialized hardware like sensors, PLCs (Programmable Logic Controllers), or SCADA (Supervisory Control and Data Acquisition) systems.

- Software: The programming environment and tools used to create the graphical user interface (GUI), set the logic for interactions, and connect the interface to the underlying machinery or process. Popular HMI software tools include WinCC, FactoryTalk, and InduSoft.

- Communication Protocols: These are the methods and standards through which the HMI communicates with the machine or industrial control system. Common communication protocols include Modbus, OPC, Ethernet/IP, and Profibus.

- User Interface (UI): The graphical layout and elements that operators interact with, such as buttons, switches, charts, alarms, and data readouts. An intuitive UI design is critical to ensuring a smooth user experience.

- Logic: This defines how the HMI will respond to user inputs and machine outputs. It includes the control actions, alarms, and the flow of data between different system components.

Why is HMI Programming Important?

HMI programming is crucial for several reasons:

- Increased Efficiency: Well-designed HMI systems allow operators to monitor and control machines with ease, reducing the chances of human error and improving operational efficiency.

- Real-Time Monitoring: HMI systems provide real-time data visualization, enabling operators to make informed decisions quickly. This is particularly important in industries like manufacturing, where delays in decision-making can lead to costly downtime.

- Enhanced Safety: HMI systems can be programmed with safety features like alarm triggers, emergency stop buttons, and system diagnostics. This ensures that operators can respond to critical situations promptly, minimizing risks to both personnel and equipment.

- Troubleshooting and Diagnostics: HMIs often include diagnostic tools that help operators and maintenance personnel quickly identify and resolve issues in the system. This can helps reduce downtime and maintenance costs.

- User-Friendly Interface: Complex industrial processes can be difficult to manage without a clear interface. HMI programming ensures that operators can control and monitor systems without needing extensive technical knowledge, thus improving user adoption and reducing training costs.

HMI Programming Best Practices

To ensure the success of an HMI programming project, it is important to follow some best practices:

1. Prioritize User-Centric Design

The ultimate goal of HMI programming is to make it easier for the user to control and monitor the system. Therefore, the design of the user interface should be intuitive and user-friendly. Follow these guidelines:

- Simple Layout: Avoid cluttering the screen with too much information. Use logical groupings and clearly labeled buttons to make navigation easy.

- Consistent Design: Maintain consistency in terms of colors, icons, and symbols. This ensures that operators don’t have to spend time figuring out how to interact with the system.

- Use of Visual Cues: Use graphical elements such as color-coding and shapes to indicate the status of processes (e.g., green for normal operation, red for alarms).

- Customizable Views: Depending on the complexity of the system, offer customizable views that allow users to focus on the parameters most relevant to them.

2. Ensure Real-Time Data Display

The main advantage of HMI systems lies in their ability to display real-time data. It is essential to program the system to update the data accurately and at regular intervals. For instance, the values displayed on the HMI should reflect the actual machine status, such as temperature, pressure, and speed, in real time.

3. Consider Data Logging and Trending

Many industrial systems require continuous monitoring of key performance indicators (KPIs) over time. Implementing data logging and trending features on the HMI allows operators to track historical data and recognize patterns or abnormalities. This functionality is invaluable for predictive maintenance, performance analysis, and troubleshooting.

4. Implement Alarm Management

Alarms are crucial for indicating faults or abnormalities in the system. An HMI system should be able to:

- Display a clear and descriptive alarm message.

- Prioritize alarms based on their severity (e.g., high-priority alarms should be more visible or use distinct colors).

- Allow operators to acknowledge and clear alarms.

- Provide links to related diagnostic information or troubleshooting steps.

5. Test and Validate the System

Before deploying an HMI system in a live environment, thorough testing is critical. This includes:

- Functionality Testing: Ensure all buttons, switches, and controls work as intended.

- Performance Testing: Test the system’s performance under normal and peak load conditions to ensure smooth operation.

- User Testing: Involve operators in the testing process to confirm that the interface is user-friendly and meets their needs.

Tools and Software for HMI Programming

Several software tools are commonly used for HMI programming. Here are a few popular ones:

- Siemens WinCC: A widely used HMI software that supports real-time data processing, alarm management, and advanced visualization tools. WinCC is often paired with Siemens PLCs for seamless integration.

- Rockwell Automation FactoryTalk: A suite of industrial automation software that includes HMI design, data acquisition, and system monitoring. It is known for its user-friendly interface .

- InduSoft Web Studio: A versatile software that enables the creation of web-based HMIs. It supports multiple communication protocols and is often used in industries that require remote monitoring.

- Wonderware InTouch: A powerful HMI tool known for its flexibility and ease of use. It supports advanced features such as real-time data trending, multi-user environments, and remote access.

Conclusion

HMI programming is an essential skill for designing systems that allow humans to interact with complex machines. The effectiveness of an HMI system directly impacts operational efficiency, safety, and user experience. By understanding the key components of HMI systems, following best practices, and utilizing the right tools, you can create an intuitive and efficient interface that enhances your industrial operations.

Whether you are developing a new HMI system or improving an existing one, the focus should always be on creating a user-friendly, reliable, and efficient experience for the operator. The future of industrial automation and control systems lies in seamless human-machine interaction, and mastering HMI programming is a crucial step in that direction.

If you’re looking to get started with HMI programming or need help developing an HMI system for your operations, feel free to contact us. We are here to provide expert solutions tailored to your needs.